Oil pressure, the real story

Oil pressure, the real story

A customer changes their brand of oil and then complains of low oil pressure ... is this perception or reality and is low oil pressure inherently bad, why don't customers complain about high oil pressure?

Customers who change brand and experience an increase in oil pressure usually show delight, when in fact they should show concern.

The first thing we have to understand is the word 'pressure' ... Pressure is resistance to flow

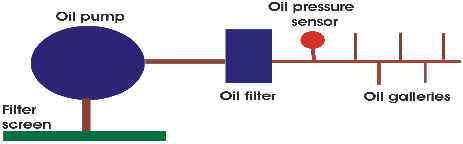

In the simplified diagram below, the oil in an engine is picked up from the sump by the oil pump through a filter screen, and then pumped through the oil filter and on through the oil galleries.

A pressure sensor is usually placed down stream of the filter to monitor the oil pressure the read out being the oil gauge in your dash.

The most important criterion for good lubrication is OIL FLOW, not oil pressure

** Low oil pressure is not necessarily bad, in fact it can be very beneficial within limits

** High oil pressure is not necessarily good, in fact it can be cause for concern

As pressure is resistance to flow, an engine with wide oil galleries and using a low viscosity oil will have a faster flow rate and lower oil pressure, a very desirable condition for minimising wear.

Conversely, an engine with smaller galleries and a higher viscosity oil will have less oil flow and a higher oil pressure, resulting in less efficient lubrication. In extreme cases, the oil would never get to the critical parts to do it's job of lubrication and reducing wear, and in some instances the oil would 'by pass' through a valve fitted to most engines, that is to allow the oil to return to the sump, reducing the amount of oil getting to the those moving parts.

High oil pressure (to high) can actually cause damage to seals and components, and should be seen as an indication of poor flow.

Cold start, When an engine starts from cold, all of the oil is in the sump.

The oil pump cannot deliver oil pressure until it has sucked up the oil and has begun pushing the oil through the galleries, hence cold start lubrication is best achieved from an oil with good cold flow Properties. This is essential as wear is most experienced at cold start due to the lack of oil available to engine components.

You may have noticed that your oil gauge reads higher at cold start up, this is telling you have more resistance to flow, and probably at a point in time you need faster flow (less pressure).

At this point and until the engine warms up and the oil pressure stabilises, you do not have proper lubrication.

Until stable oil pressure is obtained, wear rates are high due to inadequate lubrication and a sign of a good oil is one that gives stable oil pressure the fastest.

So when you change brands and experience higher cold oil pressure, think of the above.

Normal operation

Under ideal circumstances, oil pressure should be stable within reason, and any large increase or decrease should be investigated for possible mechanical damage. Consult your Vehicle hand book or experienced service centre to learn of the correct oil pressures your Vehicle manufacturer designed the engine to run on, both cold and hot.

In Summary

- Watch for any large decrease or increase in pressure from normal, this usually suggests that you have a fault and it should be investigated.

- Remember, Correct flow is more important to lubrication than pressure

- Choose a good quality oil with a high Viscosity Index to minimise thinning at temperature.

- Cooling is an important function of any engine oil, and flow rates effect this.

Do not be fooled by those oil companies building a 'thicker' oil under a standard viscosity rating so you will endorse their product over others, based on the false premise of higher oil pressure is better.

Beware of high oil pressure, it may cause damage.